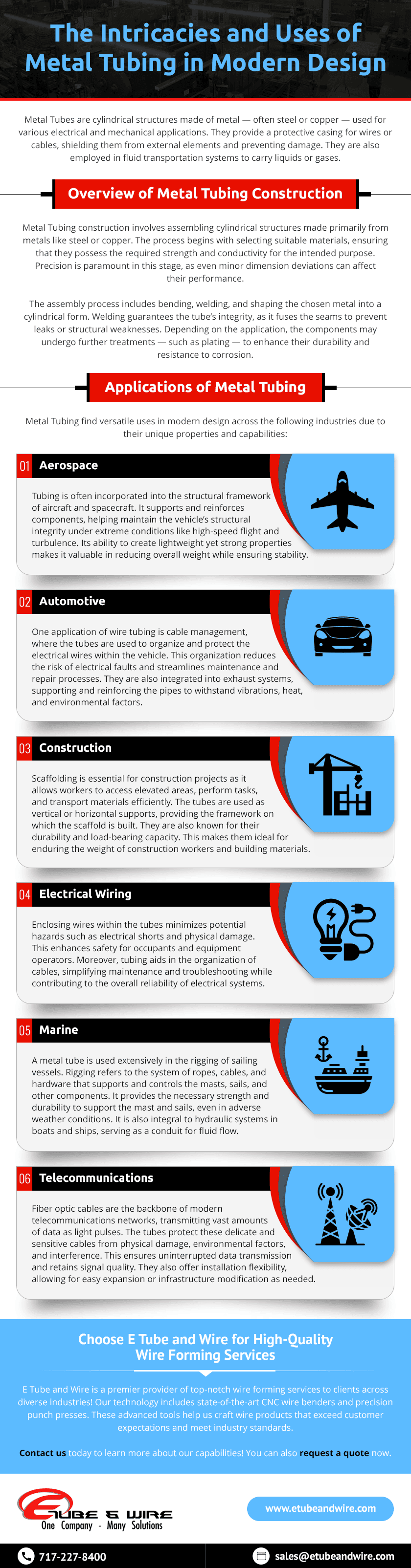

Metal Tubes are cylindrical structures made of metal — often steel or copper — used for various electrical and mechanical applications. They provide a protective casing for wires or cables, shielding them from external elements and preventing damage. They are also employed in fluid transportation systems to carry liquids or gases.

This article will explore how metal tubing is constructed and how it may be used in modern-day designs.

Overview of Metal Tubing Construction

Metal Tubing construction involves assembling cylindrical structures made primarily from metals like steel or copper. The process begins with selecting suitable materials, ensuring that they possess the required strength and conductivity for the intended purpose. Precision is paramount in this stage, as even minor dimension deviations can affect their performance.

The assembly process includes bending, welding, and shaping the chosen metal into a cylindrical form. Welding guarantees the tube’s integrity, as it fuses the seams to prevent leaks or structural weaknesses. Depending on the application, the components may undergo further treatments — such as galvanization — to enhance their durability and resistance to corrosion.

Applications of Metal Tubing

Metal Tubing find versatile uses in modern design across the following industries due to their unique properties and capabilities:

Aerospace

Tubing is often incorporated into the structural framework of aircraft and spacecraft. It supports and reinforces components, helping maintain the vehicle’s structural integrity under extreme conditions like high-speed flight and turbulence. Its ability to create lightweight yet strong properties makes it valuable in reducing overall weight while ensuring stability.

Automotive

One application of wire tubing is cable management, where the tubes are used to organize and protect the electrical wires within the vehicle. This organization reduces the risk of electrical faults and streamlines maintenance and repair processes. They are also integrated into exhaust systems, supporting and reinforcing the pipes to withstand vibrations, heat, and environmental factors.

Construction

Scaffolding is essential for construction projects as it allows workers to access elevated areas, perform tasks, and transport materials efficiently. The tubes are used as vertical or horizontal supports, providing the framework on which the scaffold is built. They are also known for their durability and load-bearing capacity. This makes them ideal for enduring the weight of construction workers and building materials.

Electrical Wiring

Enclosing wires within the tubes minimizes potential hazards such as electrical shorts and physical damage. This enhances safety for occupants and equipment operators. Moreover, tubing aids in the organization of cables, simplifying maintenance and troubleshooting while contributing to the overall reliability of electrical systems.

Marine

A metal tube is used extensively in the rigging of sailing vessels. Rigging refers to the system of ropes, cables, and hardware that supports and controls the masts, sails, and other components. It provides the necessary strength and durability to support the mast and sails, even in adverse weather conditions. It is also integral to hydraulic systems in boats and ships, serving as a conduit for fluid flow.

Telecommunications

Fiber optic cables are the backbone of modern telecommunications networks, transmitting vast amounts of data as light pulses. The tubes protect these delicate and sensitive cables from physical damage, environmental factors, and interference. This ensures uninterrupted data transmission and retains signal quality. They also offer installation flexibility, allowing for easy expansion or infrastructure modification as needed.

Choose E Tube and Wire for High-Quality Wire Forming Services

E Tube and Wire is a premier provider of top-notch wire forming services to clients across diverse industries! Our technology includes state-of-the-art CNC wire benders and precision punch presses. These advanced tools help us craft wire products that exceed customer expectations and meet industry standards.

Contact us today to learn more about our capabilities! You can also request a quote now.