Fan Guard Machine

A fan guard is a physical barrier placed around spinning fan blades to prevent accidental contact. It’s an important piece of equipment in any metalworking shop, as it helps protect workers and other objects from potentially dangerous flying debris created by the machines. But beyond metalworking, the fan guard machine has other applications.

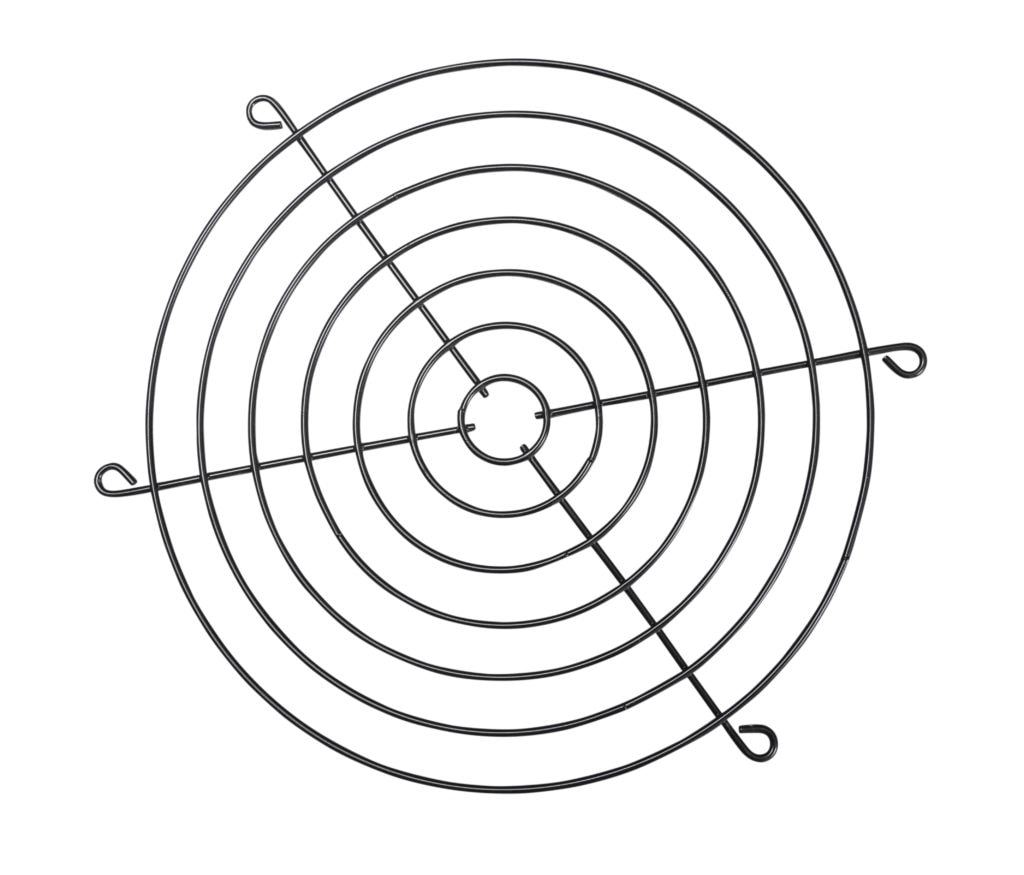

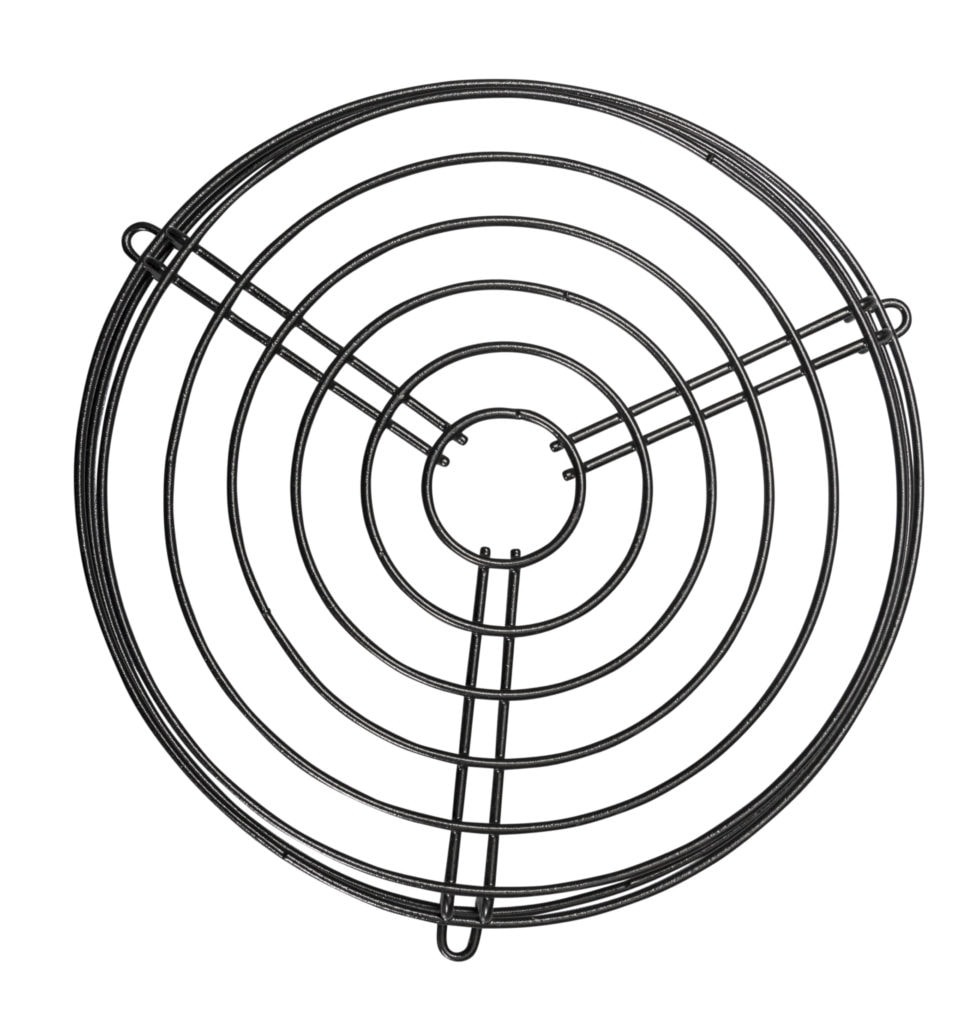

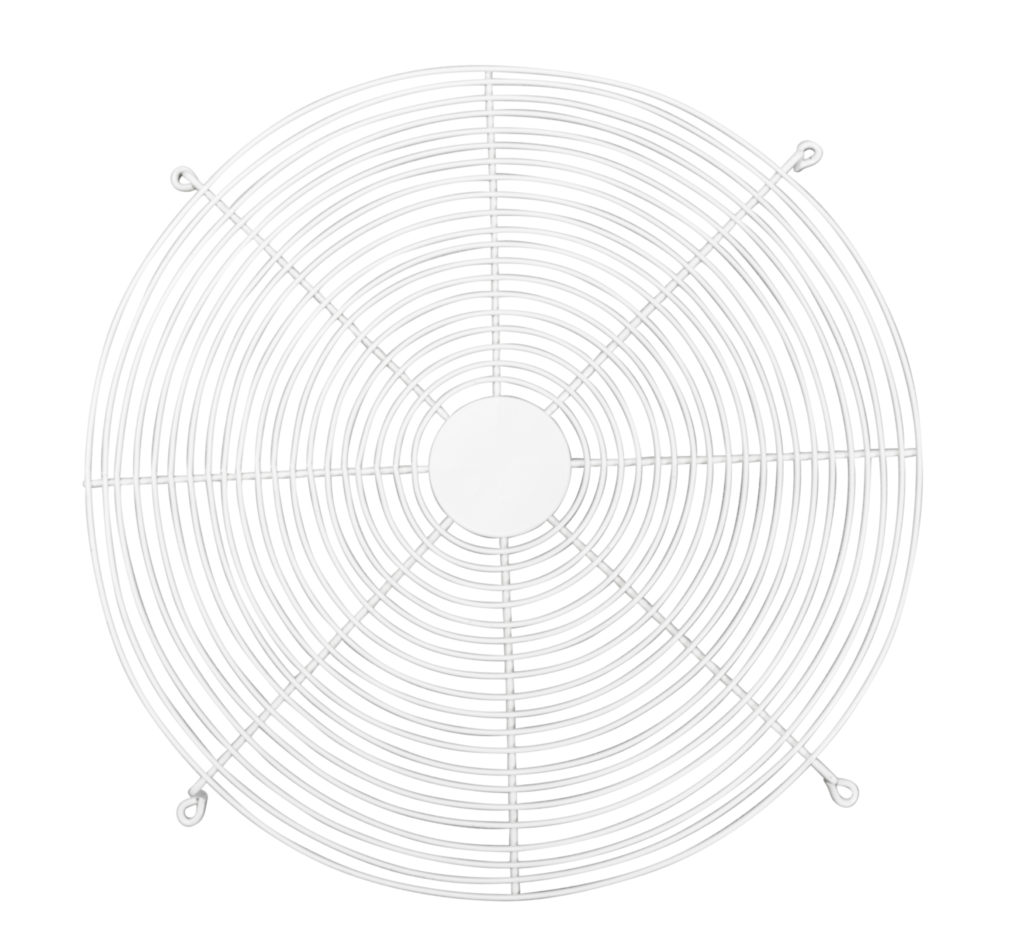

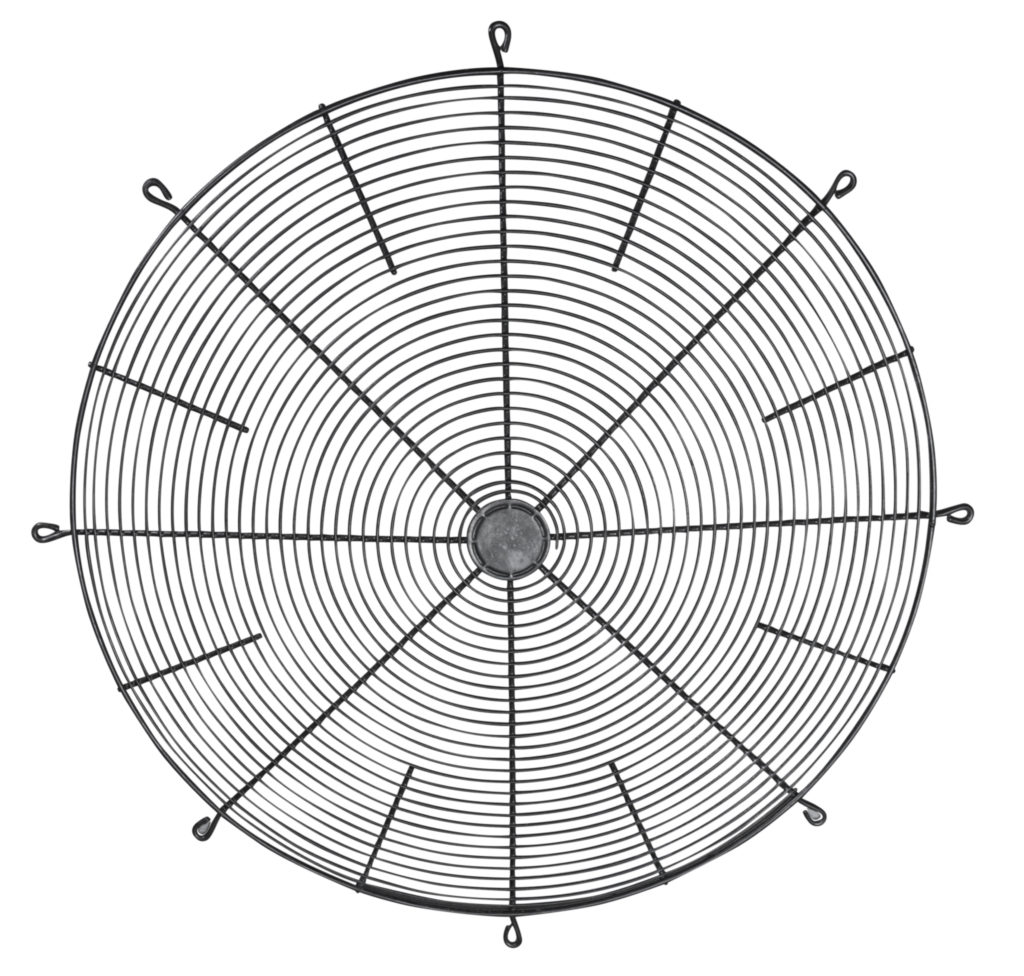

Fan guards are typically made from metal wire and can be manufactured through cutting, bending, welding, and surface treatment. But they can also be made from other materials, including plastic and fabric. Available in a wide range of configurations — such as rectangular, circular, dome, spiral wire, and more — they’re designed to fit around fan blades and help deflect any foreign objects that could potentially damage the blades.

Fan guards minimize noise by absorbing some of the sound vibrations. They also improve the fan’s efficiency by allowing air to flow more freely.

Fan Guard Machine Applications

Fan guard machines have various applications across different industries. Some common uses include:

- Computers and other electronics: Fan guards can help reduce the amount of noise produced by computers and other electronics. By covering the spinning fan blades, fan guards can help to reduce the amount of noise produced by the fan. In addition, fan guards can also help prolong the fan’s life by preventing damage to the blades. Fan guards come in various sizes, including 40, 60, 80, 92, 120, and 140mm, to match diverse application needs.

- Industrial fans: Fan guards are an effective way to improve indoor air quality in industrial settings. They are widely used in industrial fans that draw contaminated air from the building or workspace. Industrial fans work to protect employees from harmful airborne particles and other undesirable components.

- Process cooling fans: Fan guards can also be used on cooling fans in large-scale industrial process equipment such as heat exchangers, process dryers, cooling towers, etc. They can help protect the equipment from wind and water damage, improving its efficiency and extending its life.

- Material handling or pneumatic fans: Fan guard machines are placed on material handling or pneumatic fans to help keep the area around the fan clean. By preventing debris from entering the fan, the fan guard machine helps to reduce the risk of damage to the fan and the surrounding equipment. This allows the fans to propel granular materials efficiently.

- HVAC fans: HVAC systems circulate air around a space to regulate temperature and humidity levels. But they can spread dust and other airborne particles throughout the room if not well maintained. This can be a health hazard for occupants and a fire risk. To help prevent these problems, HVAC systems often have fan guards installed. Fan guards help keep the system clean by trapping dust and other particles before entering the airflow. They also help to protect the fan blades from damage.

Fan Guard Capabilities

Fan guards are important safety devices with so many capabilities. A good quality fan guard will:

- Keep objects from making impact with the blades of the fan, protecting the equipment from wind, water, debris, dust, etc., that cause damage. This ensures the fan works efficiently.

- Protects personnel from accidental injury. A fan guard is a physical barrier between the spinning blades and the surrounding area. Implementing a fan guard will protect against accidental contact with the fan blades while still allowing for adequate airflow.

- Extend the life of your fan by keeping debris from damaging the blades.

- Improves fan performance by limiting external components.

Fan Guard Machines from E Tube and Wire

Fan guard machines are a great way to keep personnel safe and protect your equipment. If you are looking for a fan guard machine, E Tube and Wire can provide you with the best options in the market. Request a quote today or contact us for more information.