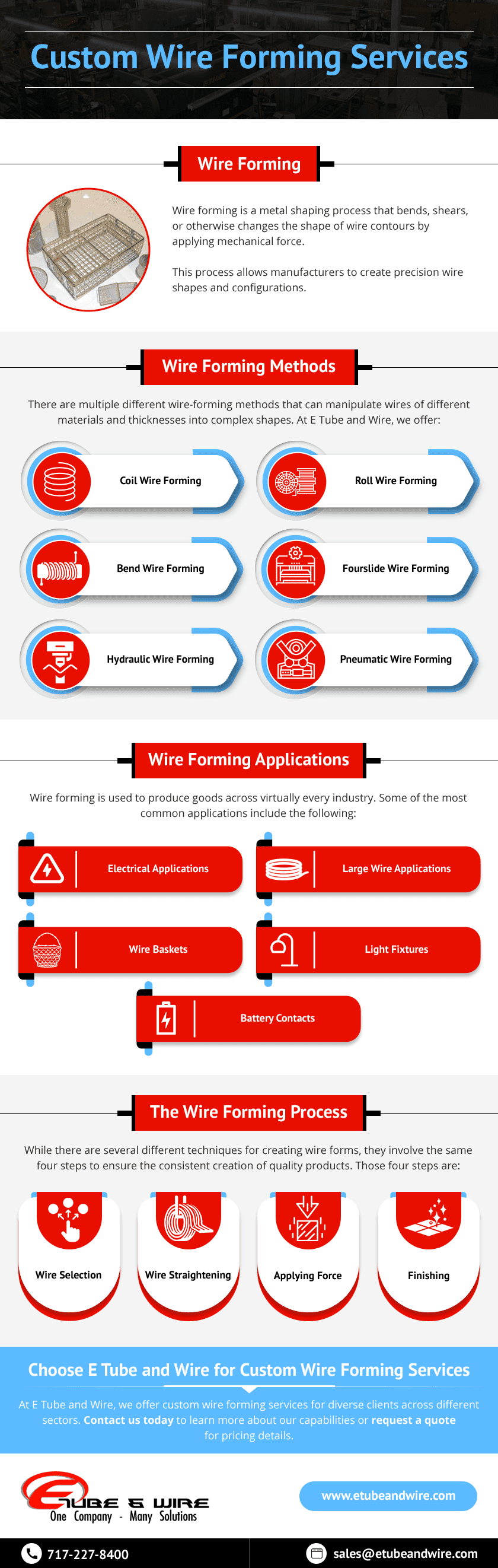

Custom Wire Forming Services

Wire forming is a metal shaping process that bends, shears, or otherwise changes the shape of wire contours by applying mechanical force. This process allows manufacturers to create precision wire shapes and configurations. At E Tube and Wire, we’re a leading provider of high-quality wire forming services. We use a combination of CNC wire benders and punch presses to form wire products across multiple different industries.

Wire Forming Methods

There are multiple different wire-forming methods that can manipulate wires of different materials and thicknesses into complex shapes. At E Tube and Wire, we offer:

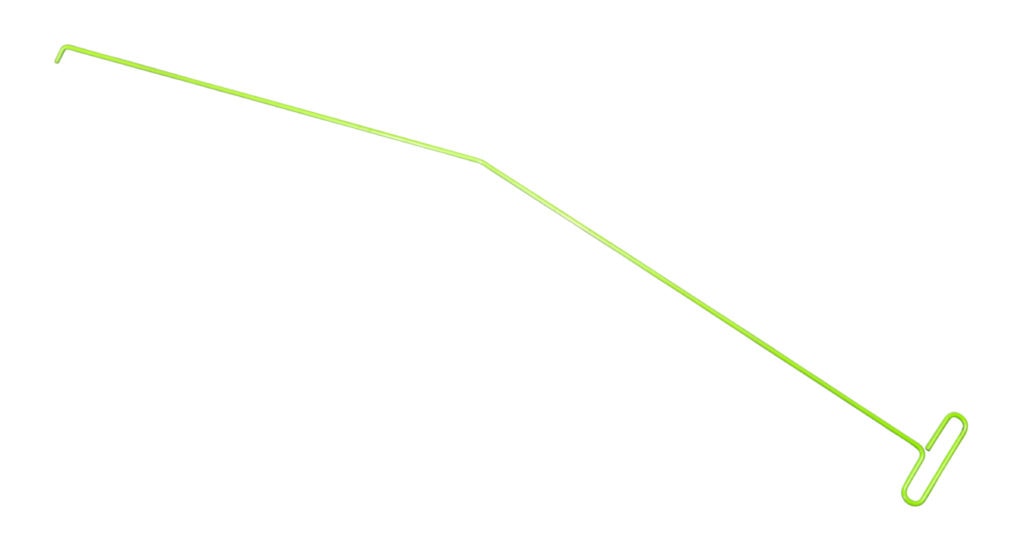

CNC Wire Bending

This process uses CNC machinery and pneumatic or hydraulic presses to bend wire up to 180°. These machines can handle a wide array of materials and wire thicknesses.

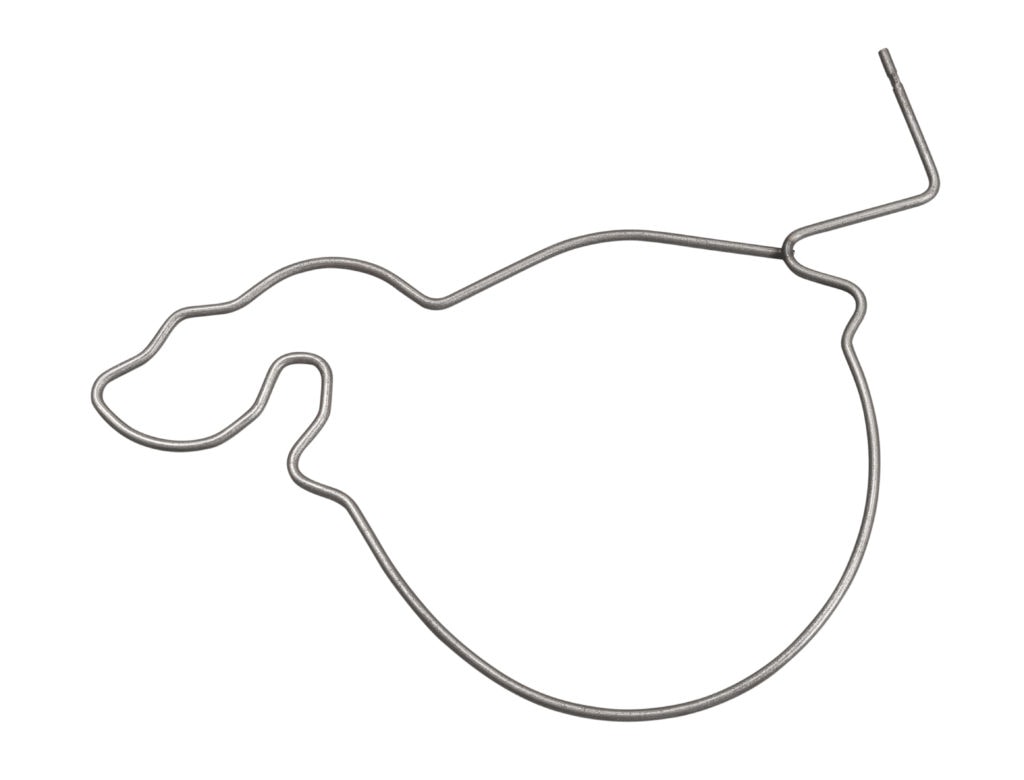

Manual Wire Forming

This process uses drawn or rotary die machinery to manually apply bends in the metal. It’s a popular choice for artistic goods, prototypes, and small orders.

Coil Wire Forming

To form consistent coils, lengths of metal wire are wrapped around a cylindrical metal blank. Electrical coils use a ferromagnetic core instead of a plain metal bank.

Roll Wire Forming

This versatile process can create multiple different shapes and bends in the metal. Manufacturers can create round, flat, and grooved shapes with rounded edges out of wire. The resulting products are hardened and can also be shaped to have chamfers, collars, threads, and more.

Bend Wire Forming

In this process, the machinery bends a length of metal prior to it being cut to length. This ensures there’s little to no product waste.

Fourslide Wire Forming

Much like a stamping press, fourslide wire forming machines shape the wire into a predetermined shape. The four sliding tools can be configured into unique shapes.

Hydraulic Wire Forming

Hydraulic wire forming presses use a hydraulic motor to move the rollers and press the wire into a specific shape. They are often CNC machines.

Pneumatic Wire Forming

Pneumatic wire forming processes operate similarly to hydraulic wire forming, except the rollers are controlled by air-driven processes rather than fluid-driven processes.

Wire Forming Applications

Wire forming is used to produce goods across virtually every industry. Some of the most common applications include the following:

- Electrical Applications: Wires can form antennas, clips for cables and electrical wiring, and more.

- Large Wire Applications: Thick metal wire can construct heavy-duty shelves, assemblies, fasteners, and handles.

- Wire Baskets: Wire baskets are commonly used tools for holding and carrying goods in the food handling industry, hospitals and labs, material handling facilities, and more.

- Light Fixtures: Wire forms are secure hardware for creating and hanging light fixtures. These are commonly produced through CNC forming to create identical, universal forms.

- Battery Contacts: Wires forms make resilient battery contacts, especially if they’re spring formed rather than stamped.

The Wire Forming Process

While there are several different techniques for creating wire forms, they involve the same four steps to ensure the consistent creation of quality products. Those four steps are:

- Wire Selection: At this stage, manufacturers or product managers choose the right wire material for the product based on the gauge, diameter, and type of metal material. Some popular choices include steel or stainless steel for long-lasting, durable parts, and aluminum or copper for consumer goods and decorative applications. Metals ranging from carbon steel to aluminum, brass, and specialty alloys can each be used for wires.

- Wire Straightening: Because wire is often stored in coils, it needs to be carefully straightened before it can be formed. Machine rolling processes can both straighten the wire and remove stress from the material that can interfere with the process.

- Applying Force: Each of the processes listed earlier involve applying force to the wire to shape and bend it. Applying sufficient force can create precision shapes and ensure a long-lasting bend. Different processes can be chosen based on the complexity of the form and the volume of the order.

- Finishing: Not all wire products need finishing, but finishing processes can apply grooves or cuts, remove sharp edges, or add coatings.

Choose E Tube and Wire for Custom Wire Forming Services

At E Tube and Wire, we offer custom wire forming services for diverse clients across different sectors. Contact us today to learn more about our capabilities or request a quote for pricing details.

Specifications

| MATERIALS | Aluminum Brass Carbon Steel Copper Hastelloy Inconel Mild Steel Stainless Steel Steel Titanium |

| WIRE DIAMETER | 0.080″ Diameter through 0.500″ Diameter for Carbon Steel Standard S Hooks and C Hooks in sizes from .080 dia wire up thru 1.25″ dia wire. Up to 0.375″ for Stainless Steel Up to 1.25″ |

| INDUSTRIES SERVED | Food

Refrigeration Dyeing |

| WIRE PRODUCTS | Wire Baskets

Point of Purchase Displays Screens Grills Filters Guards and Fan Guards Wire Shelving Rotating Plating Drum Barrels & Drums Wire Hooks Plating/Painting Racks |

| FINISHING SERVICES | Electroplating Painting Passivating Plating Powder Coating PVC Plastic & Epoxy Coating |

| ENGINEERING SERVICES | 3-D CAD Designing Creating Drawings Prototyping |

| SOFTWARE USED | AutoCAD BobCAD CAM SolidWorks |

| STANDARDS MET | Meet Nuclear Regulatory Commission-1 Nuclear Quality Requirements Mil-Spec Welders Certified to Meet Federal Contract Specifications |

Wire Baskets

| MATERIAL HANDLING WIRE BASKETS | Standard Sizes: 12″ x 18″ x 6″ Deep 12″ x 24″ x 6″ Deep 18″ x 18″ x 4″ Deep |

| DIPPING AND PLATING WIRE BASKETS | Standard Mesh Options: Standard Sizes: 10″ x 10″ 10″ x 12″ 12″ x 12″ 16 Mesh .028. 16″ x 16″ 18″ x 18″ 18″ x 24″ 4 Mesh .080 6″ x 6″ 8 Mesh .063 8″ x 8″ Perforated Baskets also available in all above sizes in 1/16, 3/32, 1/2, 3/16 gauge. |

| ULTRASONIC CLEANING WIRE BASKETS | E Tube & Wire produces wire baskets in a variety of standard sizes to fit most ultrasonic cleaners. |

| LABORATORY / MEDICAL WIRE BASKETS | All wire baskets are manufactured to customer’s specifications and design services are available. |

| SPIN DRYER WIRE BASKETS | Mesh Sizes: Standard Sizes: 12″ x 12″ 16 Mesh .028 -1/16, 3/32, 1/8, 3/16 and 1/4 Perforated 18″ x 18″ 18″ x 24″ 2 Mesh .080 24″ x 24″ 24″ x 30″ 4 Mesh .080 6″ x 6″ 8 Mesh .063 |