Wire Services Offered

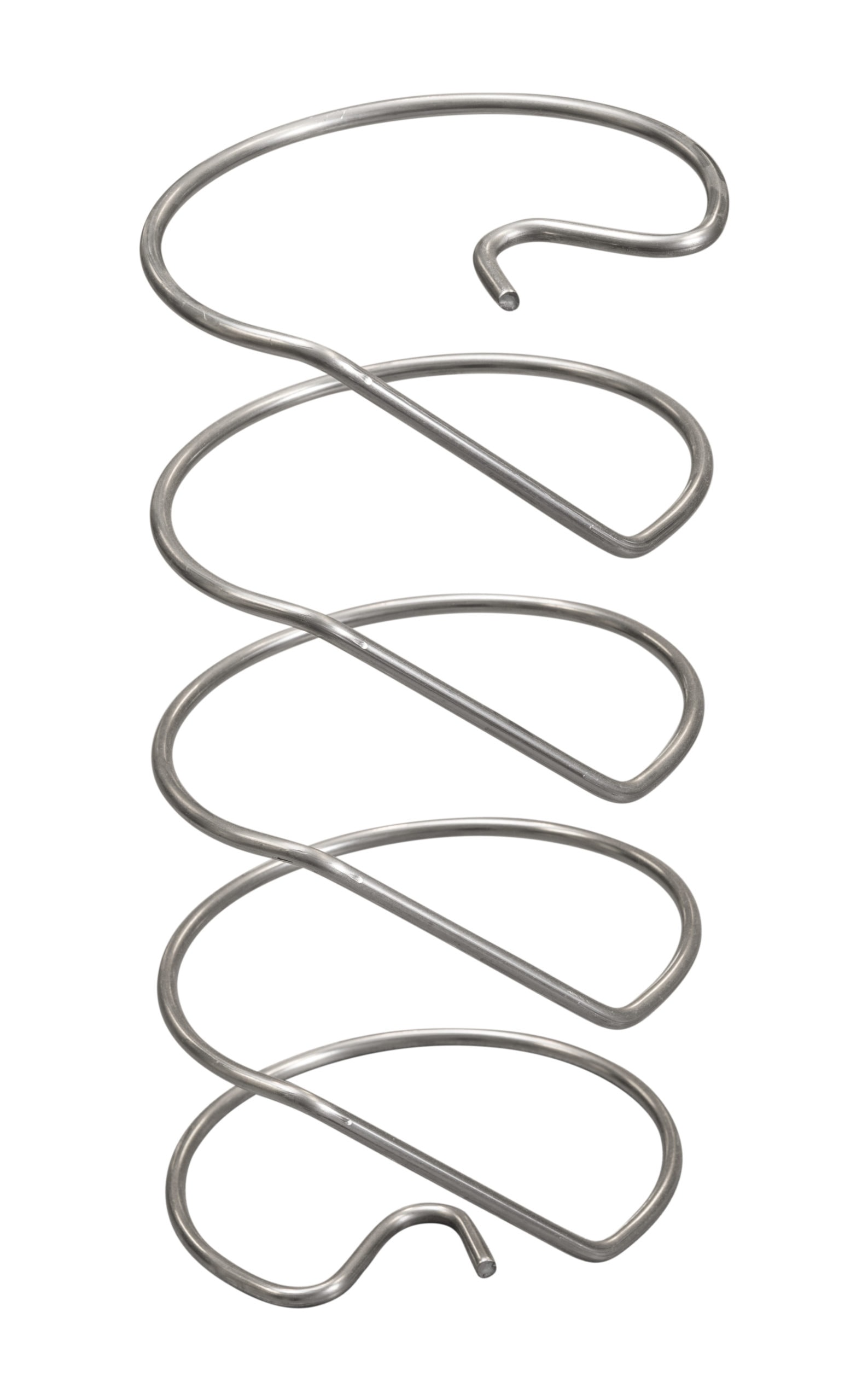

Custom Wire Forming Services

We specialize in complete design & fabrication of different types of wire formed products, ranging from wire baskets to grills. Our facility has CNC wire benders and punch presses to perform multiple operations such as forming, cutting, and bending for fabricating wire products. E Tube & Wire also manufactures wire assemblies such as novelty items, displays, and carriers using sheet metal plus machined components.

[Read More]CNC Tube Bending Services

E Tube & Wire offers tube bending services for various industries and specializes in components for the food processing industry. Aluminum, copper, and stainless steel tubing up to 3″ in diameter are precision bent at our facility. Our job shop is equipped with an array of manual, CNC, hydraulic, and pneumatic tube benders to handle diverse requirements. We maintain an inventory of mandrels and dies to process tubes at low tooling cost.

[Read More]Laser Cutting Services

E Tube and Wire’s 2D CNC laser cutting capabilities can handle jobs that range from prototyping to high volume production. We regularly cut steel, stainless steel, and aluminum to tight tolerances for the needs of our customers. We complement our laser cutting services with CNC press brakes, plate rolling, and welding services.

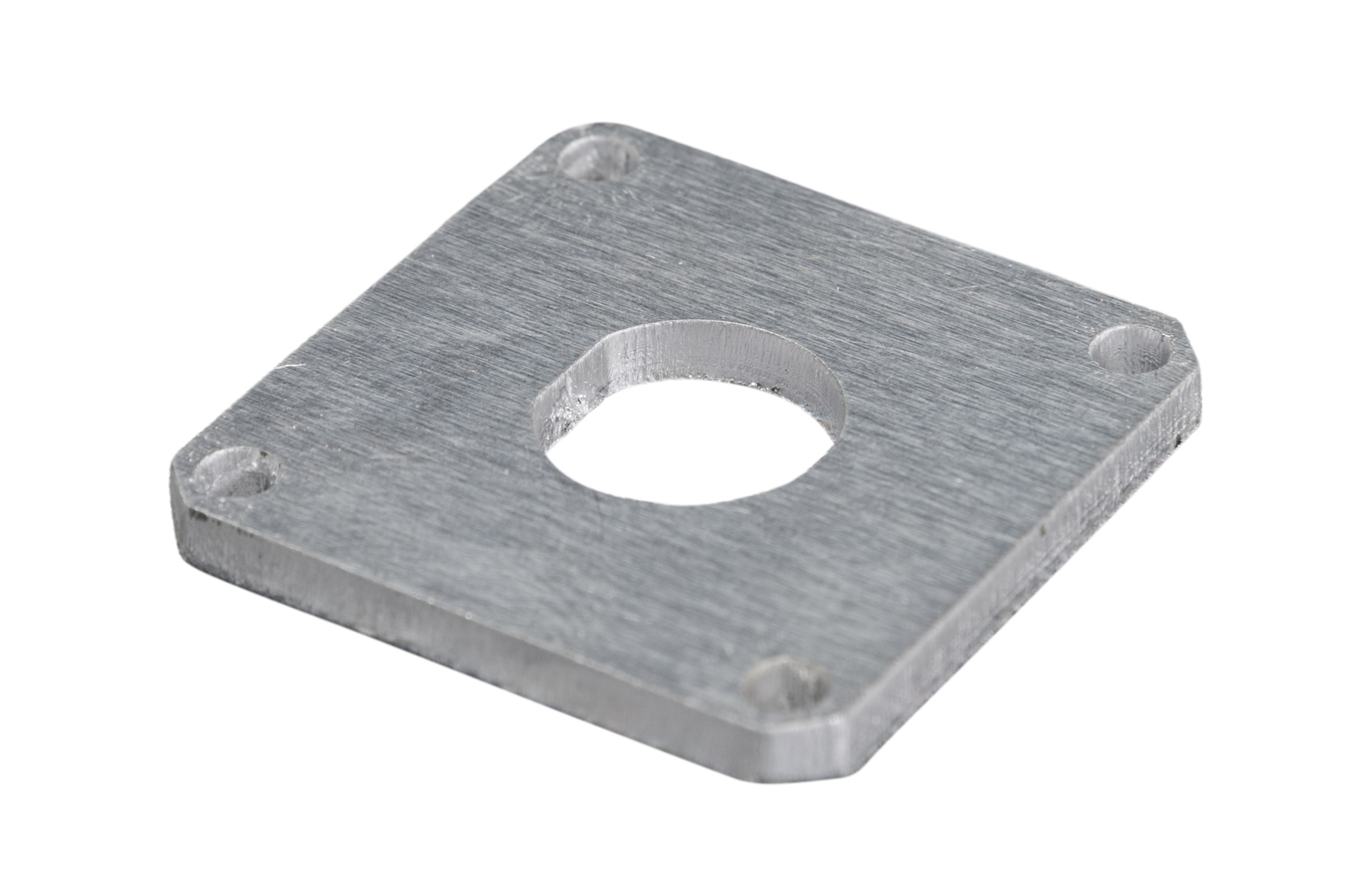

[Read More]CNC Precision Machining Services

We offer CNC precision machining services for machine assemblies, punching dies, and engineered parts. Our machine shop is equipped with CNC mills as well as CNC lathes to manufacture custom milled and turned components. Steel, stainless steel, bronze, and brass are some typical materials we handle.

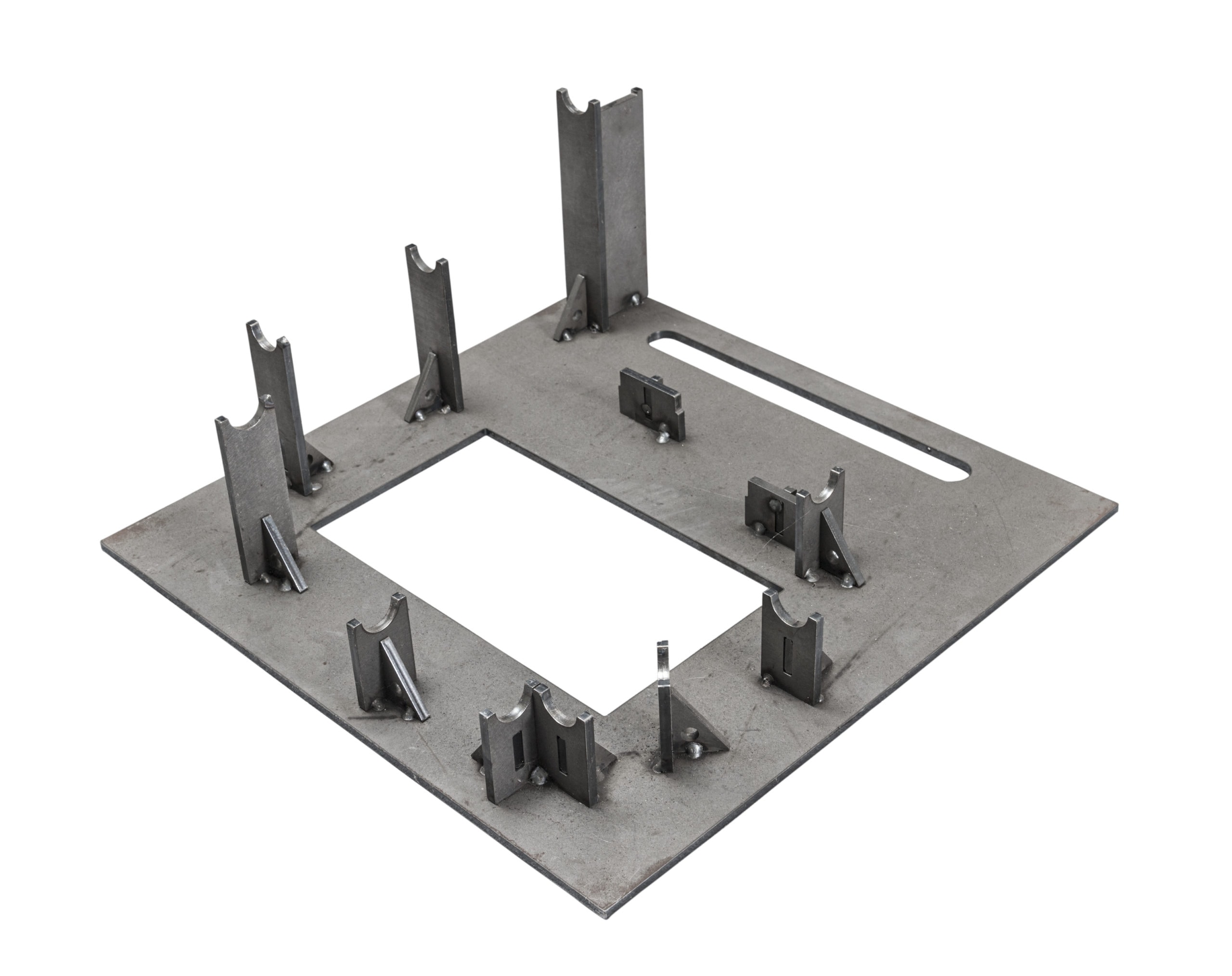

[Read More]Custom Metal Fabrication And Machine Design Services

From shearing and tube bending to punching and robotic welding, our fabrication capabilities are diverse. With a wide range of MIG & TIG weld stations, belt grinders, band saws, shears, and plasma cutting stations, we handle high volume production jobs with efficiency. Our press brakes are available with CNC back gauges for automated bending and forming of different metals. In addition, we also create assemblies of all sizes through fabrication.

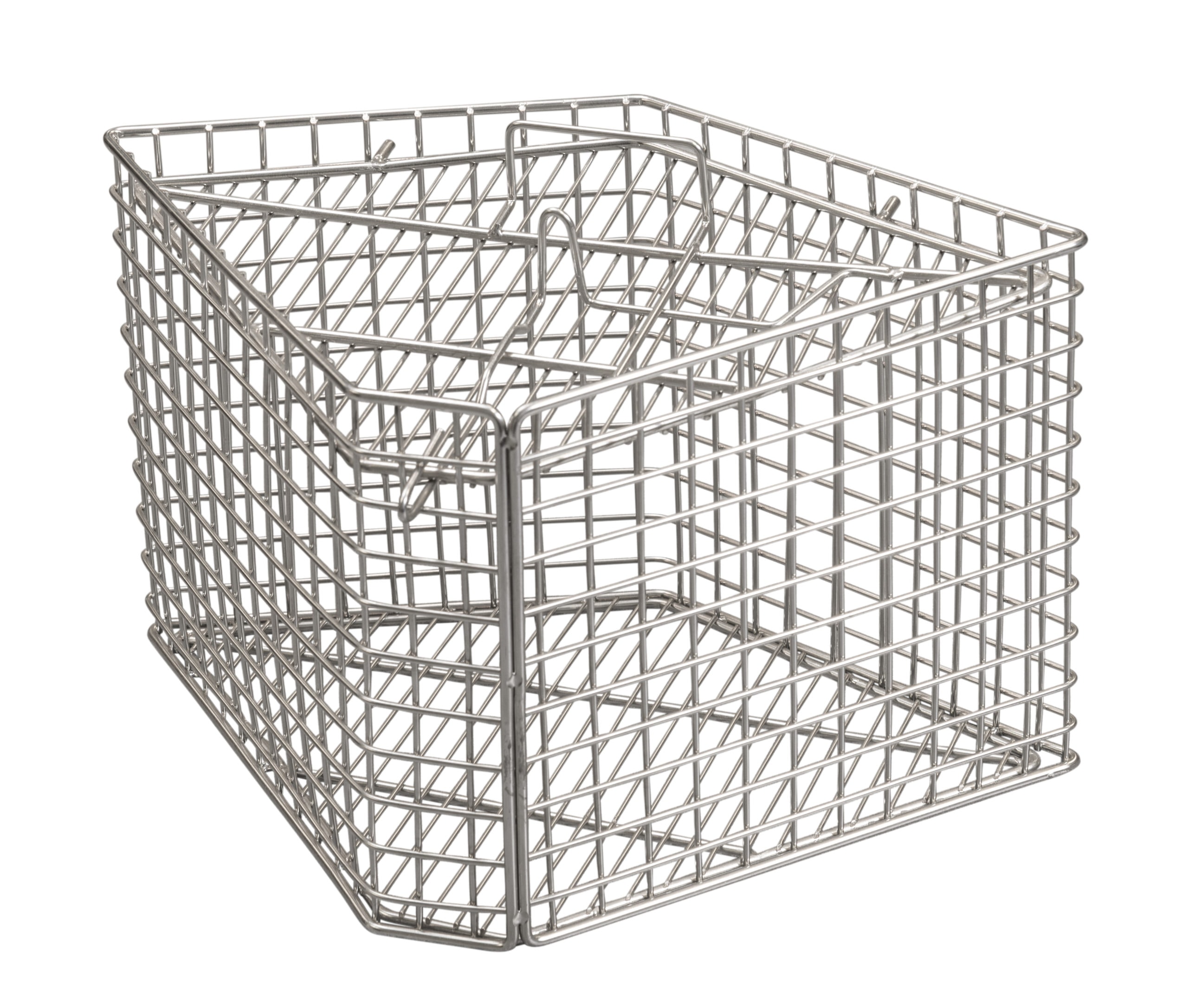

[Read More]Custom Wire Baskets

From shearing and tube bending to punching and robotic welding, our fabrication capabilities are diverse. With a wide range of MIG & TIG weld stations, belt grinders, band saws, shears, and plasma cutting stations, we handle high volume production jobs with efficiency. Our press brakes are available with CNC back gauges for automated bending and forming of different metals. In addition, we also create assemblies of all sizes through fabrication.

[Read More]Tube Plasma Cutting

Tube plasma cutting is a profile cutting process that uses advanced technology and hot plasma to effectively and efficiently cut through a material. When a plasma torch expels a stream of high-speed gas like nitrogen, argon, or oxygen from its nozzle, a high-voltage electrical arc ionizes the gas flowing through a confined electrode. The gas transfers energy from the electrode to the tube workpiece’s surface, with some of the gas changing to plasma. The heat of the plasma melts through the metal in the precise location the operator wishes to cut, and the high-velocity gas blows away the melted material.

As part of our custom manufacturing and fabrication capabilities, E Tube and Wire utilizes plasma cutters backed by CNC press brakes to provide precision forming and high-quality tube, wire, and sheet metal products. Read on to learn more about plasma cutting for tubes and how our turnkey services can support your business.

[Read More]