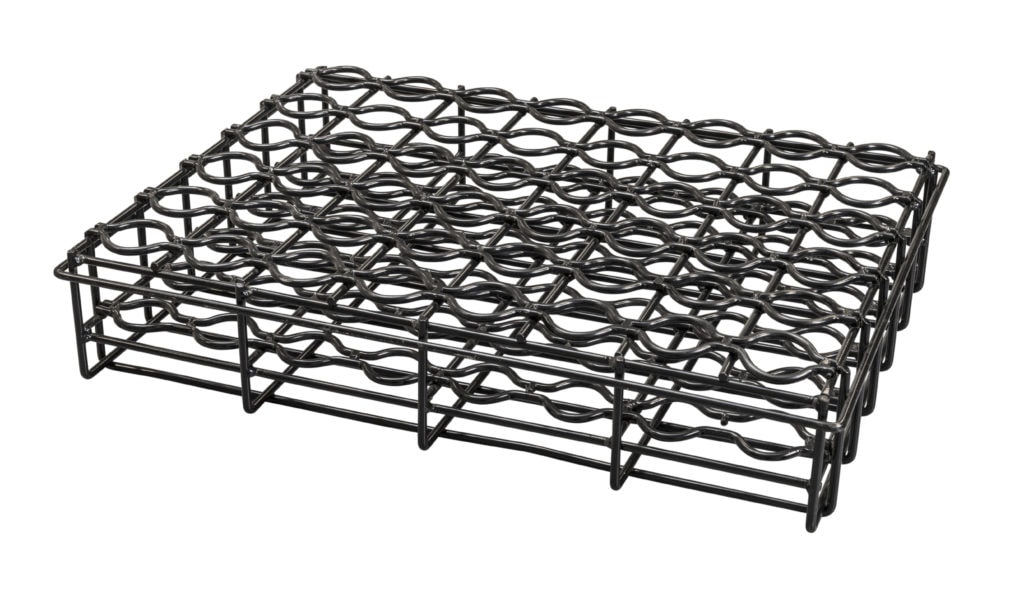

Custom Wire Baskets

Businesses in a diverse range of industries depend on the knowledge and experience of E Tube & Wire for their custom wire basket fabrication needs. Our skilled engineers tailor every detail of your wire basket to meet the needs of your application. We can help you find the ideal shape and materials to produce high-quality baskets that last for years or decades.

Custom Made Wire Basket Applications

We adapt our custom-made wire baskets for many industries. Long-lasting wire baskets provide solutions for applications such as:

- Food handling. Food production requires specialized tools to transport food through the processing equipment that must meet FDA regulations for cleanliness. Food processing baskets require flawless fabrication, as any mistake can significantly impact the safety of the food being processed.

- Medical industry. The medical industry uses numerous different wire basket forms. There are many processes that rely on stainless steel baskets due to their cleanliness and ability to be thoroughly sterilized. Choosing materials and coatings that can tolerate chemicals and temperatures is essential for these applications. Certain materials, such as grade 316 stainless steel, are highly durable and well-suited to medical applications.

- Material handling. Manufacturing processes, regardless of the type of end product, all require material handling solutions. For example, a wire basket may be required to hold a part during a manufacturing or finishing process. Hoist baskets are used throughout many industries to streamline assembly processes. If you’re working with a caustic material or simply dealing with heavy substances, custom wire baskets offer a versatile solution.

Custom Wire Basket Capabilities

E Tube & Wire can design and produce custom wire baskets for any industry or application thanks to our expert staff and advanced fabrication equipment. Our capabilities include:

Design

We use SolidWorks software to assist customers with the design and engineering process for custom wire basket fabrication. This software, combined with our knowledge and experience, allows us to develop specialized wire forms that meet all of our client’s demands.

CNC Wire Bending and Punch Pressing

At E Tube & Wire, we use computer numerical control (CNC) wire benders and punch presses to execute operations such as cutting, forming, and bending for our wire products. Our CNC wire benders work with stainless steel material up to 0.375 inches in diameter and carbon steel wire from 0.080-0.500 inches in diameter. Additionally, we have manual wire bending equipment which works with wire products up to 1.25 inches in diameter. We also have punch presses, nibblers, notchers, and welding machines available.

Finishing

Whatever finishing services you’re looking for, E Tube & Wire has an abundant selection to choose from. We will ensure your custom wire basket is finished appropriately for your application. Our finishing capabilities include:

- Electroplating

- Painting

- Passivating

- Plating

- Powder coating

- PVC plastic and epoxy coating

Custom Wire Basket Fabrication From E Tube & Wire

At E Tube & Wire, we are your one-stop-shop for all custom wire basket fabrication needs. Our 86,000-square-foot facility and extensive machining capabilities allow us to provide customers with expertly crafted components. We work with you through every phase of the manufacturing process, from design to delivery. Challenging or unique design and finishing requirements are not a problem for our expert team.

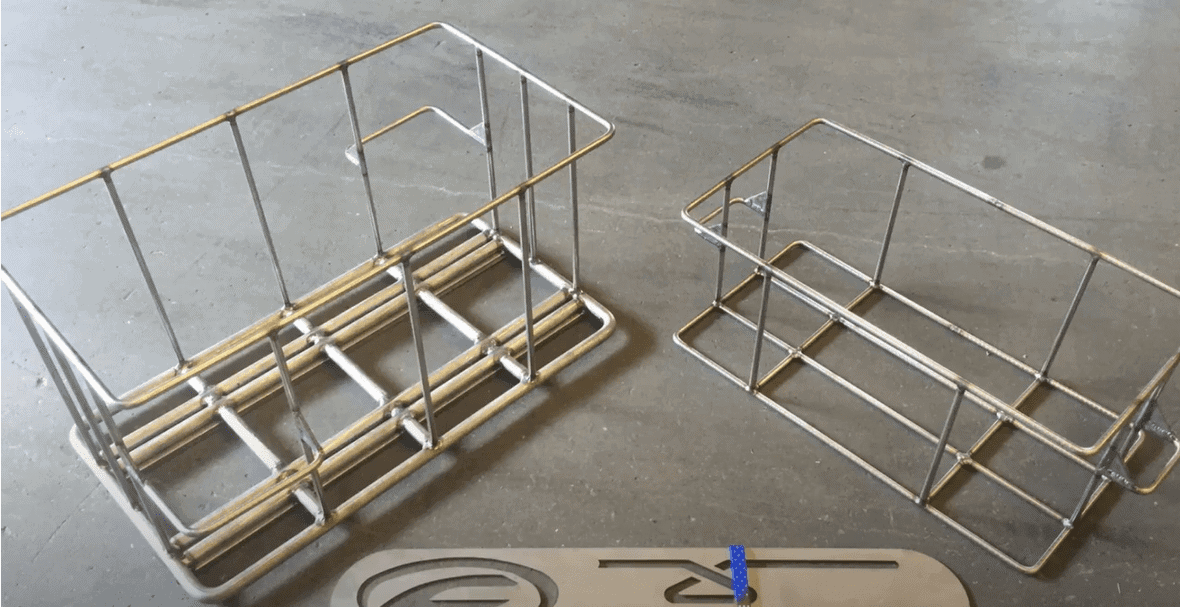

We have a wide selection of custom-made wire basket options to choose from, including:

- Material handling baskets

- Baskets for dipping and plating

- Ultrasonic cleaning baskets

- Laboratory and medical wire baskets

- Spin dryer baskets

There are many applications for wire baskets. While their end usage varies by industry and use case, all custom wire basket solutions should be highly durable, expertly designed and produced, and provide the customer with an excellent value. To get started on your customized solution, contact us or request a quote today.

Wire Baskets

| MATERIAL HANDLING WIRE BASKETS | Standard Sizes: 12″ x 18″ x 6″ Deep 12″ x 24″ x 6″ Deep 18″ x 18″ x 4″ Deep |

| DIPPING AND PLATING WIRE BASKETS | Standard Mesh Options: Standard Sizes: 10″ x 10″ 10″ x 12″ 12″ x 12″ 16 Mesh .028. 16″ x 16″ 18″ x 18″ 18″ x 24″ 4 Mesh .080 6″ x 6″ 8 Mesh .063 8″ x 8″ Perforated Baskets also available in all above sizes in 1/16, 3/32, 1/2, 3/16 gauge. |

| ULTRASONIC CLEANING WIRE BASKETS | E Tube & Wire produces wire baskets in a variety of standard sizes to fit most ultrasonic cleaners. |

| LABORATORY / MEDICAL WIRE BASKETS | All wire baskets are manufactured to customer’s specifications and design services are available. |

| SPIN DRYER WIRE BASKETS | Mesh Sizes: Standard Sizes: 12″ x 12″ 16 Mesh .028 -1/16, 3/32, 1/8, 3/16 and 1/4 Perforated 18″ x 18″ 18″ x 24″ 2 Mesh .080 24″ x 24″ 24″ x 30″ 4 Mesh .080 6″ x 6″ 8 Mesh .063 |