CNC Tube Bending Services

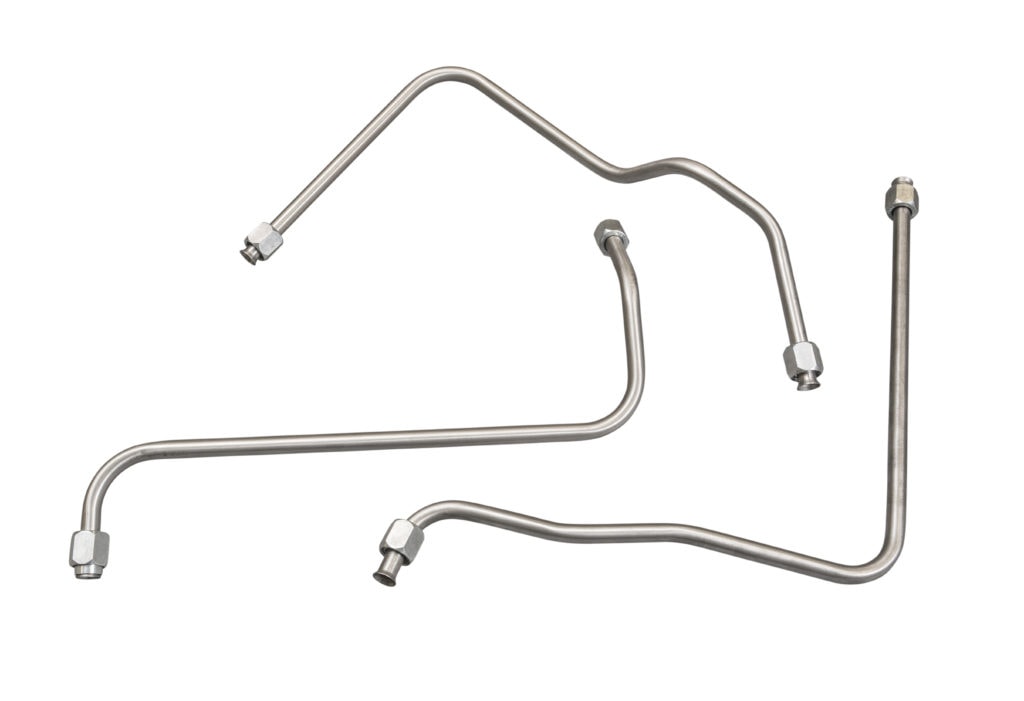

E Tube & Wire offers CNC mandrel tube bending services for various industries and specializes in components for the food processing industry. Aluminum, copper, and stainless steel tubing up to 3″ in diameter are precision bent at our facility. Our job shop is equipped with an array of manual, CNC, hydraulic, and pneumatic tube benders to handle diverse requirements. We maintain an inventory of mandrels and dies to process tubes at low tooling cost.

We offer CNC tube bending services for tubes with round, rectangle, and square cross sections to the specified tolerances. Custom metal tube benders are used for rectangular or square tubing. Our hydraulic tube benders produce tubular components that comply with stringent Mil-Spec standards. E Tube & Wire also has end-finishing machines to flair, swage, reduce, and expand tube components. Special assembly operations such as bending, assembling, and brazing are also handled. For more information on our custom metal tube bending capabilities, explore our projects gallery and specifications table below.

Specifications

| MATERIALS | Aluminum Brass Carbon Steel Copper Hastelloy Inconel Mild Steel Stainless Steel Steel Titanium |

| MINIMUM ROUND MATERIAL | 3/16” Diameter x .019 wall at 3/8” Center Line Radius |

| MAXIMUM ROUND MATERIAL | 3” Diameter x .250 wall |

| CAPABILITIES | Assembly CNC Bending End Finishing Welding/Brazing |

| END FINISHING | Expanding Flaring Reducing Swaging |

| INDUSTRIES SERVED | Food

Refrigeration Dyeing |

| FINISHING SERVICES | Electroplating Painting Passivating Plating Powder Coating PVC Plastic & Epoxy Coating |

| APPLICATIONS | Dairy Plants Orange Juice Plants Pasteurization Plants OEM Manufacturers Parts Washing |

| SOFTWARE USED | AutoCAD BobCAD CAM SolidWorks |

| STANDARDS MET | Meet Nuclear Regulatory Commission-1 Nuclear Quality Requirements Mil-Spec Welders Certified to Meet Federal Contract Specifications |

| ENGINEERING SERVICES | 3-D CAD Designing Creating Drawings Prototyping |

Types of Tube Bending

There are many tube bending methods available, each of which offers unique advantages that make it suitable for different bending projects. Some of the most commonly used are rotary bending, compression bending, and induction bending.

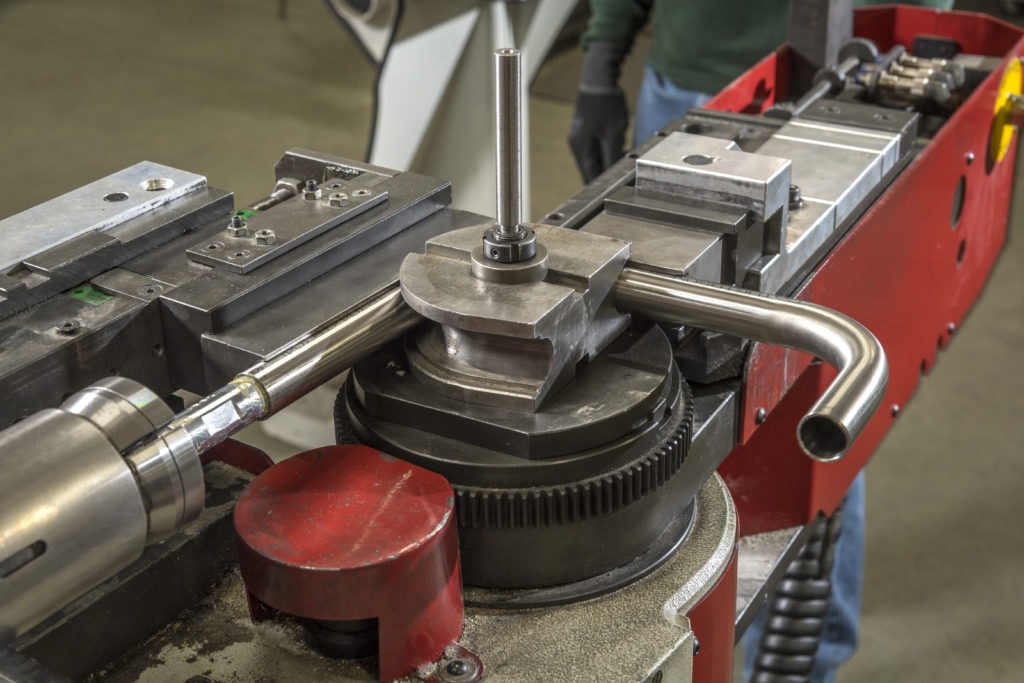

Rotary Bending

Rotary bending is the primary bending service offered at E Tube & Wire. It involves the use of a fixed die set that is machined to fit the exact outside diameter of the pipe or tube and the insertion of a mandrel to prevent the component from crimping or wrinkling during the bending operation.

Key advantages of this method include:

- Greater design freedom. Rotary bending can handle designs with sharper bend angles (e.g., more than 180 degrees) and multiple bends. The latter helps reduce the amount of post-bend processing needed to create a finished assembly.

- Broader material suitability. Rotary bending utilizes machines that generate enough force to bend dense and thick materials.

- Better production consistency. Rotary bending is highly amenable to automation, which helps improve production consistency.

Compression Bending

Compression bending involves bending the material around a stationary die. Compared to other bending methods, it offers faster processing speeds and lower per-unit tooling costs. However, it is not suitable for more complex designs or designs that need mandrels. Additionally, it carries a higher labor cost for low production volumes.

Induction Bending

Induction bending involves heating the pipe/tube and forcing it into a bend with a preset radius. As this bending method does not require any special tooling, it is highly cost-effective for small and large production quantities.

Frequently Asked Questions (FAQs) About Tube Bending

Throughout our years in business, we’ve received numerous tube bending questions from customers. Below, we provide answers to some of the most commonly asked questions.

What’s the Difference Between Tube Bending and Tube Winding?

Tube bending is a manufacturing process that creates a bend at one or more places on the tube. The bends can be made to any angle and on any axis. For example, a bent tube can have one 45° bend in the middle or a 30° bend at the top and a 60° bend at the bottom.

Tube winding is a manufacturing process that creates a continuous loop from a tube. Each newly formed coil sits atop the previous one. While the coils are generally circular, they can be made to have a square or other profile. The result is a spring-shaped component.

What’s the Difference Between Bend Radius and Bend Diameter?

Both the bend radius and bend diameter are measured in reference to the inside or centerline of the bend. The bend radius is the distance from the inside edge or center of the tube to the center of the bend. The bend diameter is the distance from the inside edge or center of the tube on one side to the inside edge or center of the tube on the other side across the center of the bend. The bend radius is one-half the value of the bend diameter.

E Tube & Wire: Your Tube Bending Partner and Expert

Looking for a partner for your next tube bending project? Turn to the experts at E Tube & Wire! We provide tube bending services to various industries, especially the food processing industry. We can bend tubing made from various materials with round, rectangular, or square cross-sections and diameters up to 3 inches. We also offer various end-finishing capabilities (e.g., flaring, swaging, reducing, and expanding) and special assembly capabilities (e.g., bending, assembly, and brazing).

To learn more about our tube bending services, check out the table below or contact us today. To discuss your bending needs with one of our team members, request a quote.