Portfolio

Medical Security Basket

E Tube & Wire worked with a customer in the medical field to develop a basket that would meet their unique security needs. The customer has a proprietary disposal process for excess drugs used in a hospital room.

The challenge was to create a basket that could be mounted to many different surfaces, be lockable, and house the container for disposal. Our designers also worked with our customer to arrive at the coating solution that would be suitable for the medical environment in which the basket will reside.

[Read More]Fan Guard Fixtures

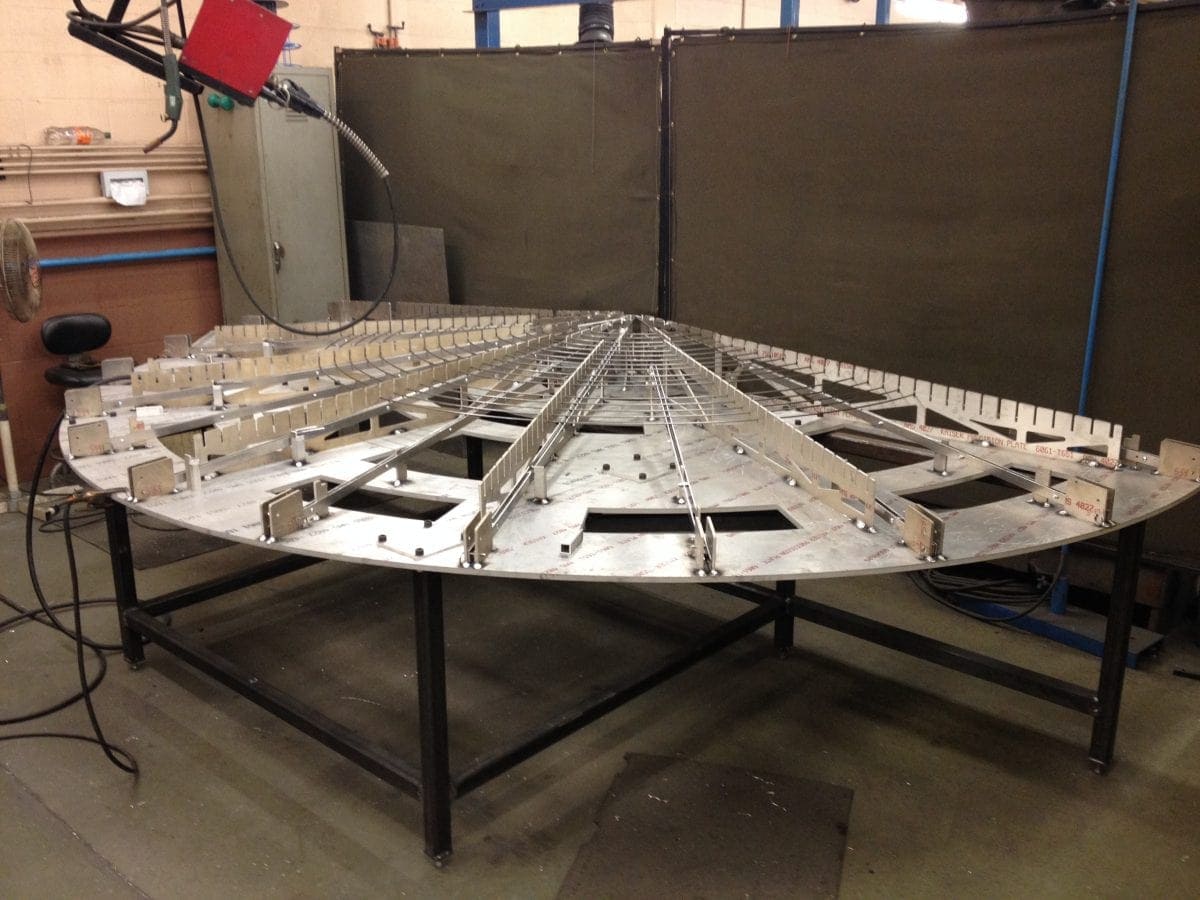

Tube & Wire created a custom fixture for a fan guard that can cover three different part sizes ranging from 9′ to 13′ in diameter. This custom design allows the fixture to change from one size to the next by moving pins. To manufacture the fixture we used SolidWorks software and had the fixture water-jet cut to the highest tolerances. The fan guards had to actually be re-drawn in SolidWorks and then a fixture was designed around that model.

[Read More]Plastic Drying Drums

E Tube & Wire helped a customer with a drying drum that is 6′ diameter and 10′ long, weighing almost one thousand pounds. This drum is used to roll the plastic in front of infrared light drying it to and below the industry standard of -40 degrees dew point. As the drum rolls the plastic moves through it while tumbling through a spiral or flights. These drums are only used in very high volume applications for large companies such as 3M.

[Read More]Tubing Weldment Fixture

This part is a hood support for the fiberglass hood on a piece of construction equipment. It acts as the metal pivot and locking points and is adhered to the hood with glue. We use the timesaver specifically to give the customer their desired rough surface finish for glue adhesion. The timesaver is basically a large automatic belt sander. These areas are then masked and the rest of the part is powder-coated at an outside vendor.

[Read More]Reverse Engineered Components

E Tube & Wire works with a local snack food company to keep their antique production machines running. They are the largest manufacturer of pretzels in the world and have upwards of 50 machines just for one size of pretzel. These machines give the food their iconic shape and size. Sometimes new equipment can’t duplicate the hand-worked or imperfect feel of a part or food that is branded as old-fashioned. Additionally, new equipment is typically not available unless it is custom built.

To provide parts and components for machines like this involves reverse engineering anything from complex castings to machined cam shafts. E Tube & Wire has a Faro inspection arm that allows precise measurements and the ability to reverse engineer parts where drawings don’t exist. We will model the part or component in SolidWorks, and then provide the customer with a drawing of that part to have it made.

[Read More]Fan Guard Machine

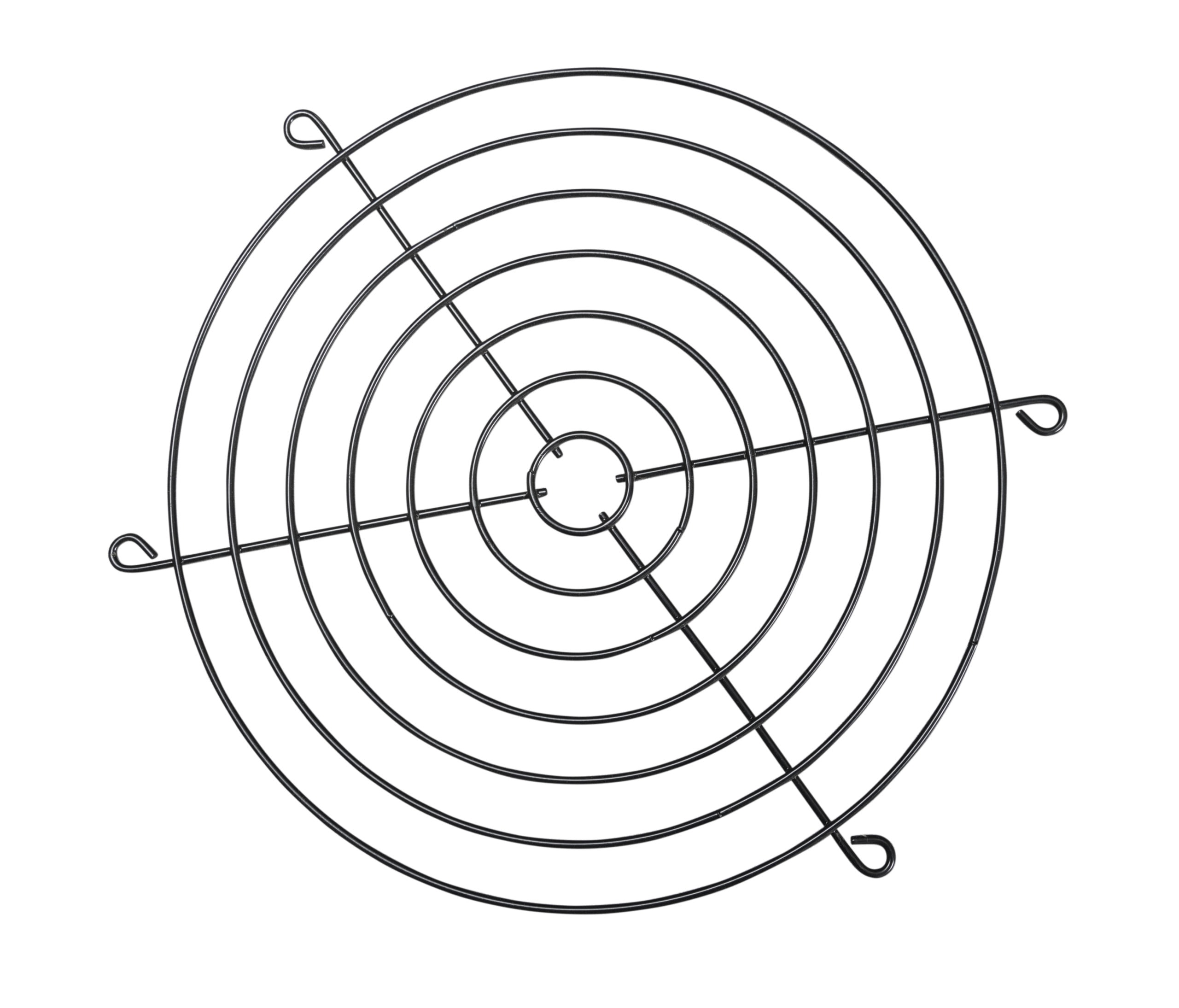

A fan guard is a physical barrier placed around spinning fan blades to prevent accidental contact. It’s an important piece of equipment in any metalworking shop, as it helps protect workers and other objects from potentially dangerous flying debris created by the machines. But beyond metalworking, the fan guard machine has other applications.

Fan guards are typically made from metal wire and can be manufactured through cutting, bending, welding, and surface treatment. But they can also be made from other materials, including plastic and fabric. Available in a wide range of configurations — such as rectangular, circular, dome, spiral wire, and more — they’re designed to fit around fan blades and help deflect any foreign objects that could potentially damage the blades.

Fan guards minimize noise by absorbing some of the sound vibrations. They also improve the fan’s efficiency by allowing air to flow more freely.

[Read More]